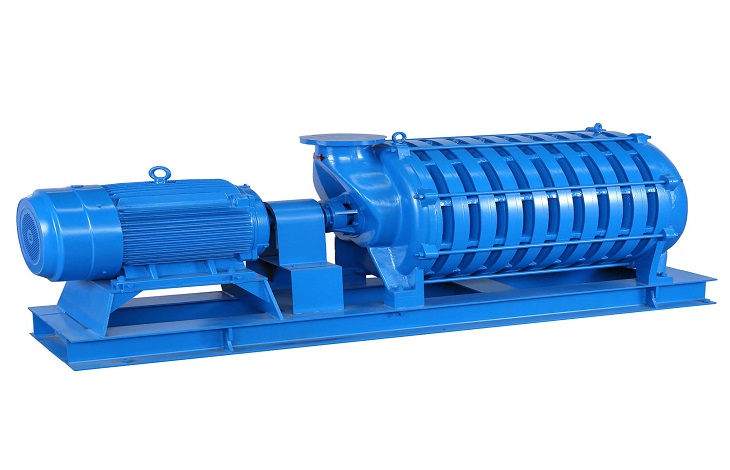

Multi-stage centrifugal blowers increase the centrifugal force by increasing the speed of air and other gases.

The versatility of centrifugal blowers makes them ideal for multiple applications. You can adjust between grade one and grade five, depending on your specific needs.

Efficiency is undoubtedly one of the standout features of multi-stage centrifugal blowers. Although it consumes energy efficiently, this machine can reach up to 30KPA of pressure.

Despite its powerfulness, this blower is remarkably quiet. Other equipment in its range are typically noisier, producing much more than the 80db produced by this machine.

Moreover, this blower has little maintenance because its outriggers are easy to remove and replace.

Depending on your preference and the intensity of your project, you can choose between a direct drive and a v-belt system. Even better, this equipment has a 12-month warranty that guarantees free replacements and repairs, provided you don’t contradict the terms and conditions.

Features of Multistage Centrifugal Blowers

Here are the top features and benefits of multi-stage centrifugal blowers.

Multiple Baffle Rings

Multiple baffle rings ensure that the air flows directly into the impeller, a process that reduces the air lost through the inlet passage. Even better, the impeller has a 2D design that increases the efficiency of the blower and its pressure and vacuum capability.

Balance Piston

This equipment has almost zero axial force, low pressure on drive bearings, enhanced rotor bearing longevity, and less susceptibility to compressed gas leakage thanks to its balanced piston system.

Advanced Impellers

2D shrouded cast aluminium impellers are keyed onto the shafts and balanced individually. After this, the components are arranged to ensure smooth operation while producing the least noise possible. For added reliability, rotor speeds are configured to operate below critical levels.

Flexible Coupling

Blowers and exhausters are connected to precision-aligned flexible coupling power sources. As a result, power transfer is optimised, and the equipment has a higher capacity for bearing loads.

Cast Housing

Cast iron is the primary material used for the construction of centrifugal blowers. Smaller equipment is made using cast aluminium. The blower is made using steel rods and mounted to its various parts using a single steel baseplate. As such, you’re assured of robustness and durability.

Labyrinth Seal

The labyrinth seal on centrifugal blowers minimises gas leakage and prevents reverse airflow. This is useful for enhancing efficiency of the equipment.

Carbon Ring Seal

Carbon Ring Seals are a more robust version of other seals. This is because they allow you to purge, further increasing durability.

Mechanical Axial sealing, also called MAXSeal, is a variant of Carbon Ring Sealing. It’s renowned for its eco-friendly nature, as it reduces fugitive emissions by as much as 70%. This makes it the perfect choice for landfill factories that handle flammable and toxic substances. Generally, it makes operations safer and lowers the cost of production.

Wrapping Up

Forget about standard centrifuges; multi-stage centrifugal blowers are the way to go. After all, they’re more efficient and friendlier to the environment. The advanced technology used in their construction also guarantees long-term effectiveness.

When choosing a dealer for this equipment, always prioritise reputation. Choose a provider with lots of positive reviews from previous clients. More importantly, select a seller with a warranty period and offers after-sale services.

Read Also:

Importance of Industrial Filtration Systems

Filtration Systems Used in The Food and Beverage Industry